When the Commission on Accreditation of Ambulance Services (CAAS) released its Ground Vehicle Standard GVS V1.0 for new ambulances in 2016, it was not finished with its work on creating positive change in emergency medical services (EMS) vehicles. In fact, it was just getting started.

“We created and published the initial CAAS Ground Vehicle Standard at the request of numerous industry associations who were seeking an ambulance standard for the broad spectrum of EMS,” states Mark Van Arnam, administrator of the CAAS GVS Standard. “These same stakeholders convinced us that there was a severe need for a standard for remounted ambulances.” As CAAS prepared for the release of GVS V2.0 in July 2019, the newly developed GVS Remount Standard that is included as part of the updated V2.0 document stands out as a major development in enhancing the safety, quality, and durability of remounted ambulances as the most rapidly growing segment of the emergency vehicle market.PROJECT KICKOFF

CAAS started its project to develop a new Remount Standard in June 2017 by convening an open Ambulance Remount Forum. That event was attended by more than 175 people who had varied interests in remounted ambulances. Participants included final stage ambulance manufacturers (FSAMs), independent remounters, EMS providers, regulators, federal partners, and other subject matter experts. Information and feedback gathered at that meeting provided the groundwork for the Remount Standard development project (“Rethinking Remounts,” JEMS, August 2017). CAAS is an ANSI-accredited standards developer organization that defines the “gold standard” for operations in the medical transportation industry. As such, CAAS operates under American National Standards Institute (ANSI) procedures for development of its standards. “CAAS developed the Ground Vehicle Standard through a two-year process that complied with ANSI’s Essential Requirements,” states Mark Postma, cochair of the GVS Committee. “We created a Remount Standard Work Group using that same process of committee members balanced by organization type.” The development of a comprehensive Remount Standard with specific and defined requirements proved to be a substantial task. “The ambulance remount business and process are complex with numerous moving parts,” says Van Arnam. “In some ways, the development of the Remount Standard was more difficult than the initial GVS V1.0 standard project for new ambulances.” After several thousand man-hours of meetings and group participation over the course of two years, the GVS Remount Standard is finally complete. “We had a rapidly growing industry segment producing critical lifesaving emergency vehicles, with basically no standards for the remounters or their products,” says Postma. “We have now set the bar by establishing real standards that must be met with a primary focus on safety.” 1 While the GVS new vehicle sticker is blue, the remount compliance sticker and accompanying documents are coded in red and provide critical vehicle information.

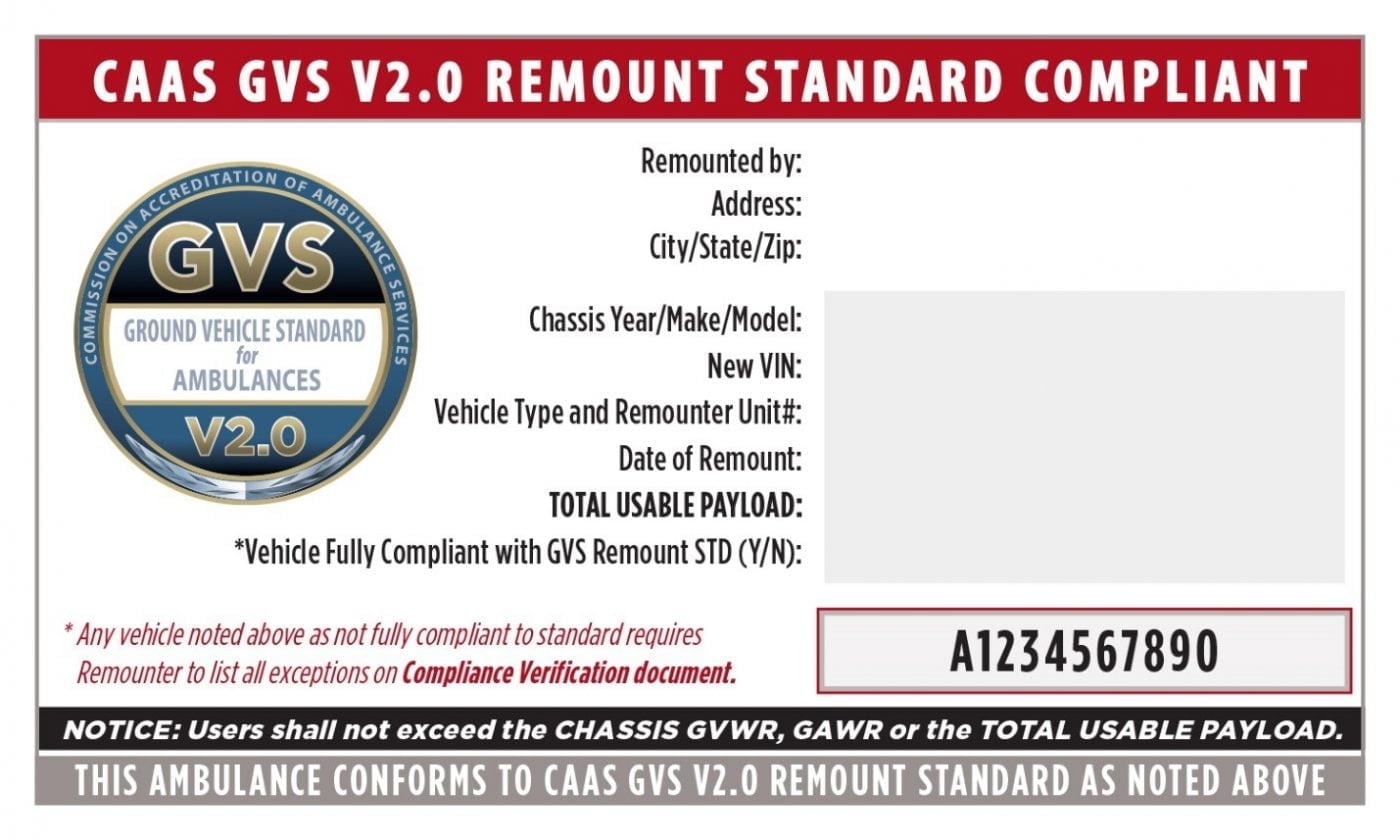

1 While the GVS new vehicle sticker is blue, the remount compliance sticker and accompanying documents are coded in red and provide critical vehicle information.

NEW CONSIDERATIONS

A review of the actual standard shows that they have done exactly that. For starters, there are requirements that the actual remounters must meet in order to comply. It is now clear that federal law considers ambulance remounters as new vehicle manufacturers. Accordingly, they are required to register with the National Highway Traffic Safety Administration (NHTSA) as such and meet the same federal requirements as any vehicle manufacturer. This includes strict compliance with all applicable federal motor vehicle safety standards (FMVSS) that apply to ambulances and their chassis. Also, remounters must meet stringent requirements for certification of multistage motor vehicles as required by federal law. This would include providing final certification of the actual vehicle as being compliant with all applicable FMVSS and NHTSA standards. In addition, remounters are obligated under the new GVS standard to provide purchasers with such items as product liability insurance coverage, garage keepers insurance coverage, vehicle warranty, and verification of financial resources.PROCESS AND PRODUCT

And, that’s not all. There is a complete section on actual production process requirements that a remounter must meet for every vehicle. This type of thing is very common for the final stage ambulance manufacturers to have, but it is likely to be new ground for many remounters. Process documentation of strict compliance with FMVSS, the incomplete vehicle document (IVD) requirements for the specific chassis used, as well as the OEM Body Builder’s Guide for that chassis are all part of the new minimum standard and something that the remounter must have and that should be provided to the purchaser on request. The remounter must have a process for determining the suitability of the existing body module to be remounted and be able to present that information accurately to the owner of the ambulance as well as performing steps to inform the purchaser of any unseen defects or deficiencies found during the remount procedure. In addition, a “Scope of Work” document is required, which includes an itemized proposal of the overall project as well as weight, balance, and minimum payload projections for the specific vehicle with the new chassis. The new standard provides special attention to FMVSS safety standards that are federal requirements and must be considered in the remount process. Specific requirements for the modular body door locks and latches as well as seats, belts, and anchorages in the patient compartment are delineated in detail. Additionally, the GVS Committee has included consideration for some of the new National Institute for Occupational Safety and Health/Society of Automotive Engineers (SAE) safety standards, currently required in all of the new vehicles for inclusion in remounts as applicable. Compliance to the new SAE standards for patient compartment seating (SAE J3026) and equipment retention (SAE J3043) are both required on a remounted ambulance for any new installation or modification of the corresponding features from that which was provided in the original production vehicle. Compliance with the new SAE J3027 Litter Integrity, Retention, and Patient Restraint requirement is required for all remounts. New safety requirements for console retention, backup camera, and antitheft device are also required for all units.TESTING AND DOCUMENTATION

The Ambulance Manufacturer’s Division (AMD) of the National Truck Equipment Association is the trade association of North American ambulance builders. It maintains and publishes the AMD standardized test methods that are used by all ambulance manufacturers for performance tests and quality control in production of new ambulances. While a few of these AMD tests are destructive-type testing for prototype vehicles, the majority of them can be used for testing a single one-off production vehicle. The GVS Remount Standard specifically identifies and requires 15 of these AMD standardized tests that must be performed on every remount produced under the standard. These tests are quite varied and cover such items as sound level, lighting performance, high-/low-voltage testing, and aspirator performance. While labeling and documentation requirements for new ambulances are well understood, this is an area that has been confusing and historically lacking on some remounts. GVS now clearly establishes the requirements and expectations for these items in remounted ambulances. First, the NHTSA federal requirement for the final stage manufacturer (remounter) to provide a final stage certification label is distinctly noted. GVS made strong advances on vehicle labeling and documentation with its V1.0 requirements for new ambulances. The GVS new “Ambulance Certification Sticker” as well as its “Vehicle Compliance and Payload Verification” documents provide the vehicle purchaser and state inspectors with vital vehicle information. The GVS Remount Standard now creates a similar labeling and documentation system for remounts. An Ambulance Remount Compliance sticker and accompanying document templates will now provide that same vital information for remounted ambulances.NOT A RECERTIFICATION

The GVS Remount Standard explicitly states that that the GVS Ambulance Remount Compliance sticker verifies that the ambulance has been remounted in accordance with the GVS Remount Standard and does not provide or imply certification to a new ambulance standard. The U.S. General Services Administration has made it clear that the original “Star of Life” certification sticker is not transferable to a remounted ambulance and that a valid certification sticker must display the correct VIN number of the chassis currently in use. A purchaser should contact its state or local EMS licensing authority to determine the eligibility of a vehicle to be relicensed within their operating area following a remount process. “The ambulance remount business has grown exponentially over the past 10 years,” states Van Arnam. “In this era of tight budgets and difficult reimbursement, the economies of remounting an ambulance can make real sense for many purchasers. It is important, however, that remounts are done without compromising the safety of the patient or the crew riding in the vehicle. The CAAS GVS Remount Standard establishes real standards for safety and quality while maintaining the economic advantages of remounting.” The CAAS Ground Vehicle Standard V2.0 including the Remount Standard can be found on the GVS Web site at www.groundvehiclestandard.org.RON THACKERY is an attorney from Denver, Colorado. He is an expert in ambulance risk and safety and a member of the GVS Committee.